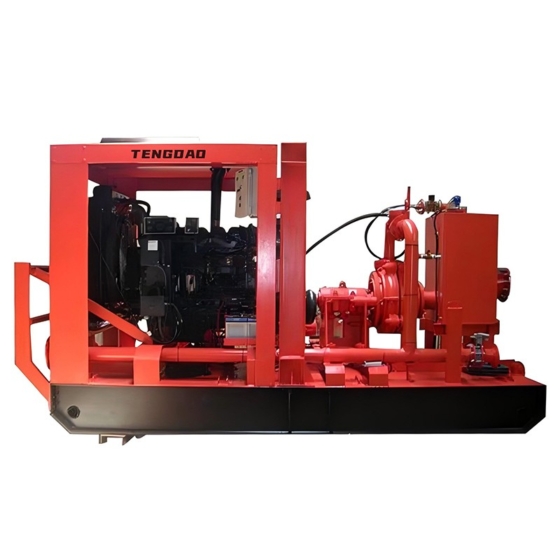

Engine-Driven Solid Particle Vacuum-Assisted Dewatering Centrifugal Slurry Pump: 개요

Technical Specifications

– **유량:** 100 받는 사람 15,000 m³/시간

– **머리:** 20 받는 사람 250 m

– **Application Environment:** Industrial mining areas, coal, and power sectors

– **Compatible Engine Brands:** 커 민 스, 퍼 킨 스, 도이츠, 위차이, 시차이, 웨이차이(威洋)

– **Device Types:** Skid-mounted, mobile, and floating

Product Overview

The engine-driven solid particle vacuum-assisted dewatering pump is a versatile water pump that sets a new standard in the industry. It is designed to be lightweight and user-friendly, capable of efficient operation in both low and high head applications. This pump is tailored to meet the growing needs of global mining enterprises as mining operations extend from shallow to deep pits.

Constructed from CA6NM material, this pump offers superior durability and wear resistance. The design features wider flow passages to accommodate larger particles, ensuring that it can handle tough conditions with ease. The vacuum assistance, at a capacity of 1.3 m³/min, provides rapid water intake, while the diesel engine’s pump coupling employs a SAE J620 direct connection with internal flexibility for high transmission efficiency. The instrument system includes waterproofing, loss-of-water protection, bearing temperature monitoring, cavitation protection, and multiple safeguards for the engine, ensuring stable and reliable operation without complex procedures.

Constructed from CA6NM material, this pump offers superior durability and wear resistance. The design features wider flow passages to accommodate larger particles, ensuring that it can handle tough conditions with ease. The vacuum assistance, at a capacity of 1.3 m³/min, provides rapid water intake, while the diesel engine’s pump coupling employs a SAE J620 direct connection with internal flexibility for high transmission efficiency. The instrument system includes waterproofing, loss-of-water protection, bearing temperature monitoring, cavitation protection, and multiple safeguards for the engine, ensuring stable and reliable operation without complex procedures.Product Introduction

The engine-driven solid particle vacuum-assisted dewatering centrifugal slurry pump is produced using advanced international technology and is available in three main series: MH, HH, and M. Each series may share many common characteristics while catering to different operational requirements.

**M, MH, and HH Series**

These series consist of cantilevered horizontal centrifugal pumps. The shaft seals can be either packing seals or centrifugal seals, and the pump outlet can be adjusted to meet specific needs, with each adjustment providing a 45° angle change. These cantilevered centrifugal slurry pumps are ideal for transporting high-concentration and corrosive slurries across various industries, including metallurgy, mining, coal ash, power generation, and building materials.

**M and MH Series**

Unlike the HH series, the pump casing, 임 펠 러, and liners of the M and MH series are made from wear-resistant metals or rubber. Notably, the liners in these pumps are replaceable, which enhances their longevity and efficiency.

these pumps are replaceable, which enhances their longevity and efficiency.

these pumps are replaceable, which enhances their longevity and efficiency.

these pumps are replaceable, which enhances their longevity and efficiency.Applications

The versatility of this pump extends to various applications, 포함:

– **Alkalis and Inorganic Salts:** Such as lime slurry, salt slurry, and carbide slag.

– **Nonferrous Metal Metallurgy:** For processing slurries from aluminum, copper, vanadium, and zinc.

– **Petrochemical Industry:** Handling sand-laden crude oil.

– **Papermaking:** Utilizing lime slurry.

– **Fermentation:** Managing slurry fermentation processes.

– **Power Generation and Environmental Protection:** Dealing with coal ash, gypsum slurry, and more.

Features and Advantages

1. **Fully Automatic Operation:** The pump can automatically draw water without manual intervention, enhancing operational efficiency.

2. **No Need for a Foot Valve:** Unlike traditional pumps that require a foot valve for proper operation, this dewatering pump eliminates that necessity, simplifying installation and reducing costs.

3. **Integrated Vacuum Pump:** Designed as a compact unit, this vacuum pump minimizes potential points of failure, thus increasing system reliability.

3. **Integrated Vacuum Pump:** Designed as a compact unit, this vacuum pump minimizes potential points of failure, thus increasing system reliability.4. **Oil-Lubricated Mechanical Seal:** The mechanical seal is oil-lubricated, allowing for 24-hour continuous operation without water, which greatly enhances durability and adaptability.

5. **Drain Valve Design:** A drain valve enables complete removal of liquid from the pump, preventing unpleasant odors and the growth of bacteria.

6. **High-Temperature Coupling:** The connection between the pump and engine uses a fully rubber high-temperature coupling to ensure stable and reliable power transmission.

7. **Adjustable Angle Hot-Dip Galvanized Quick Connect:** The quick connect fittings at the pump inlet and outlet can be adjusted, facilitating easier pipeline configuration and installation.

8. **Spherical Traction Rod and Torque Vibration Dampening:** The spherical traction rod provides stable support and guidance, while the torque dampening measures minimize vibration and noise during operation.

결론적으로, the engine-driven solid particle vacuum-assisted dewatering centrifugal slurry pump is a sophisticated and robust solution designed for various industrial applications. Its innovative features ensure efficient operation, longevity, and adaptability to harsh working environments, making it an essential tool for modern mining and industrial operations.

펌프,발전기,등대,유압 스테이션 - TENGDAO

펌프,발전기,등대,유압 스테이션 - TENGDAO