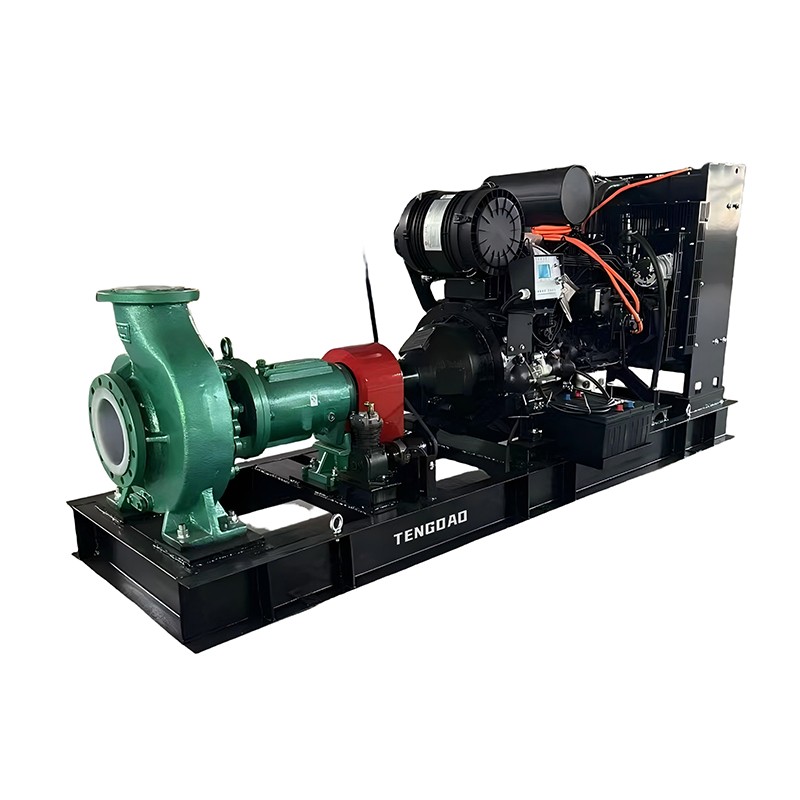

The API610 MCZ Series Diesel Engine Chemical Pump

The API610 standard serves as a benchmark for centrifugal pumps used in industrial applications, ensuring reliability, efficiency, and safety in the transportation of various liquids. Within this framework, the MCZ series diesel engine chemical pump stands out for its versatility and robust design. This type of pump is particularly employed across a range of sectors, including chemical manufacturing, petrochemical processing, refining, pulp and paper production, and sugar manufacturing, among others. Designed to meet the intricate demands of liquid transportation, the MCZ series offers a comprehensive solution that aligns with industry standards.

Product Overview and Structural Configuration

The MCZ series comprises horizontal, single-stage, single-suction cantilever centrifugal pumps that conform to the DIN24256/ISO2858 standards. Its configuration allows for easy integration into existing systems while ensuring high efficiency. Available in two structural arrangements, OH1 and OH2, the pump is capable of handling both low-temperature and high-temperature liquids. This includes neutral and corrosive fluids, whether they are clean or contain solid particulates, reaffirming its applicability across a wide spectrum of industrial processes.

Some key specifications of the MCZ series pumps include:

Flow Rate (Q): Capable of reaching up to 2000 m³/h.

Head (H): Maximum head capability of 160 meters.

Working Pressure (P): Operating up to 2.5 MPa.

Working Temperature (T): Functional range from -80°C to 300°C.

Characteristics: The pump boasts a smooth performance curve, low NPSH (Net Positive Suction Head) values, and high-efficiency ratings even under partial load conditions.

These specifications are critical in ensuring that the MCZ pump can be used efficiently across various industrial environments without compromising operational performance.

Design Features and Advantages

Design Features and AdvantagesThe design of the MCZ series reflects a thoughtful approach to operational efficiency and ease of maintenance, incorporating several advantageous features:

Standardized Dimensions: The dimensions and base plate of the pump are designed according to international standards, enabling seamless replacement of imported pumps and reducing downtime.

Inline Configuration: The pump’s suction and discharge ports are aligned on the same axis, facilitating hassle-free piping and process connections.

Integrated Assembly: The design forms a cohesive assembly of the bearing frame, shaft, impeller, and packing gland. This integration allows for maintenance to be conducted without the need to disassemble from existing piping systems, enhancing operational efficiency.

Pressure Compensation Mechanism: The axial pressure at the seal is managed through balancing holes on the impeller, providing reliable sealing solutions. Users can choose from various sealing options, including soft packing or single and double mechanical seals.

Durable Bearings: The roller bearings are designed for longevity, with a substantial shaft diameter ensuring balance during operation. Certain configurations even feature a double volute design to mitigate radial forces, further contributing to stability.

Versatile Medium Transport Capability

The MCZ series pump’s robust design allows it to transport a multitude of chemical substances across various concentrations and temperatures. The following substances are ideal candidates for transport using this pump:

A range of inorganic and organic acids, including sulfuric acid, nitric acid, hydrochloric acid, and phosphoric acid.

Concentrated alkaline solutions of sodium hydroxide and sodium carbonate at various temperatures.

Various saline solutions.

Liquid petrochemical products, organic compounds, and other corrosive materials.

To accommodate the diverse range of substances handled, our manufacturing facility utilizes a variety of corrosion-resistant materials such as 303, 305, 306, 307, 316, 316L, 904, 904L, 804, ECR alloy, Hastelloy, CD-4MnCu, and titanium alloys. The selection of materials aligns with the requirements of the specific media being conveyed, ensuring both safety and operational longevity.

The MCZ series diesel engine chemical pump exemplifies modern engineering excellence tailored for the rigorous demands of the chemical processing industry. Its ability to efficiently transport a wide variety of corrosive and neutral liquids, combined with its robust design features and adherence to international standards, underscores its role as a pivotal component in industrial applications. As industries continue to evolve and seek reliable solutions for fluid transport, the MCZ series stands as a testament to innovation and a commitment to quality in pump manufacturing. Customers are encouraged to provide detailed information regarding the specific liquids to be transported upon ordering, ensuring optimal performance and selection of materials for each application.

Pompe,Generatori,Faro,Stazione idraulica-TENGDAO

Pompe,Generatori,Faro,Stazione idraulica-TENGDAO